Introducing the K turbo engine to its new Heritage shell

Mmmm … somethings not quite working here … there’s no gearbox!

The tunnel is enlarged to take the W58 Supra gearbox

RH view of enlarged tunnel

Because the crossmember had to be removed for the gearbox, we replaced it with a ring frame – here is the topt (cockpit) side of the ring frame

In addition we double skinned the rear of the tunnel to better transmit the torsional loads to the scuttle beam – some Ks have split this seam, this reinforces that seam

The top of the tunnel is raised

Double reinforcing around the gear lever opening

The completed tunnel and bracing

And Primed

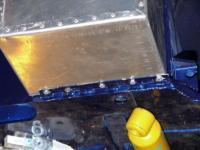

Under the car, here is the gearbox mount crossmember (welded in) and the mounting points for the removeable portion which completes the ring frame

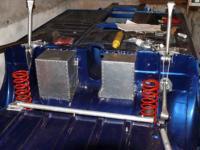

Under the car, the original bump stop member is converted to a spring mount and a turret added for the shock

Turrets for the tele shocks; holes for the battery box -nearest camera- and fuel pumps and swirl pot; the reinforcements for spring mount and the suspn top link

Additional reinforcing where the front chassis rail joins the firewall

Reinforcing to triangulate the front crossmember to the rear wishbone mount – experience has shown that when you hit a something in a hillclimb this reduces the repair bill

Reinforcement for the antirollbar mounts – experience has shown the orininal chassis rail cracks at this point when an uprated bar is fitted – a problem also with MGB’s

Engine Bay – heater ducting,battery tray removed, mounting points for replacement cross-bracing, notch at front inner of drivers footwell for manifold clearance if needed

Bracket to support the bottom of the battery box

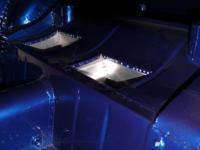

Installed battery box, from underneath

The box is a close fit around the battery so at the top we flared it over the tunnel to make room for the positive cable – grommet for cable exit at front

Battery and fuel pump boxes still leave enough room to fit diff when the axle is in place

The battery & fuel pump boxes viewed from the cockpit